Technology in plastic

Innovation needs movement

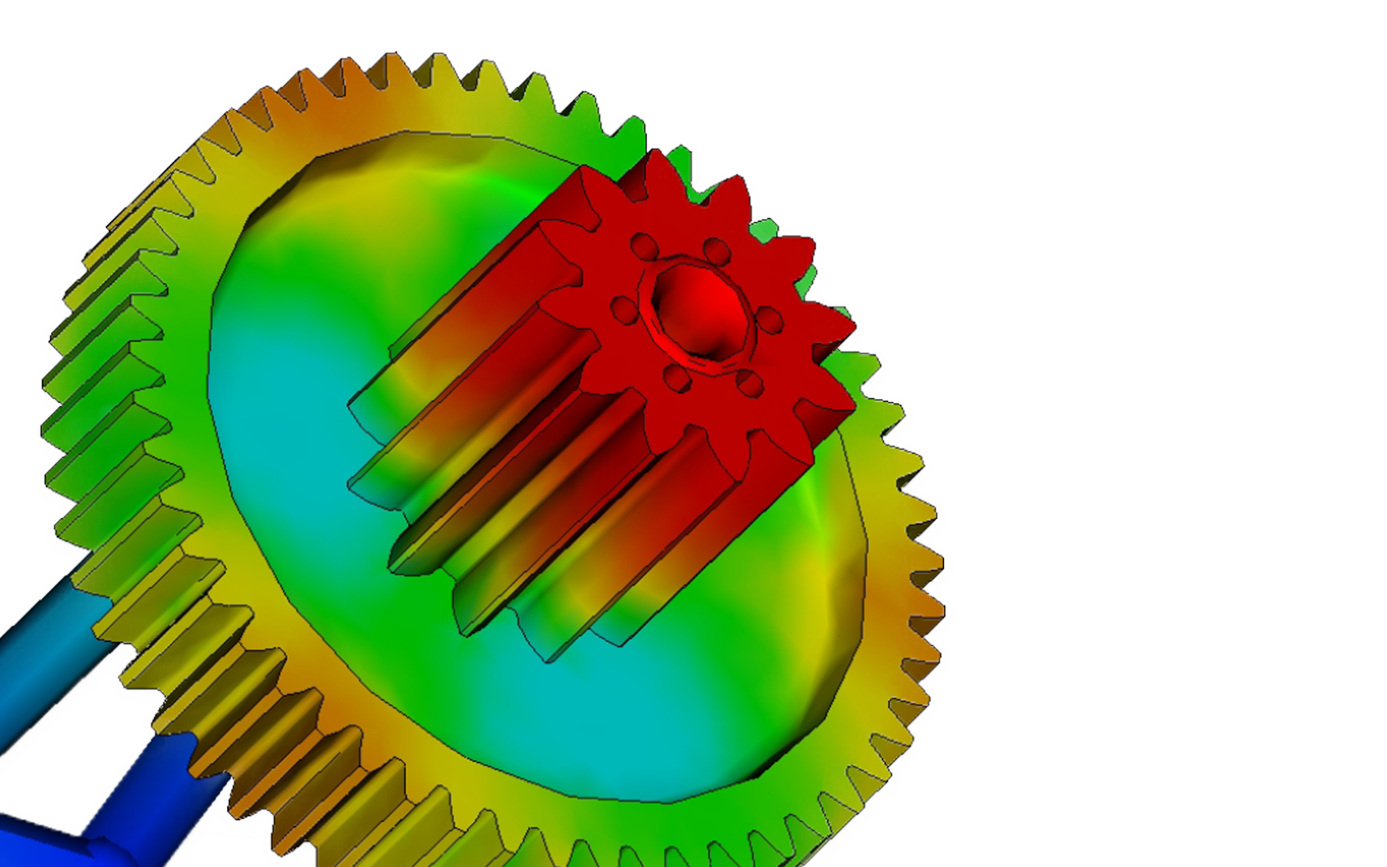

Gearing with injection moldings

When the going gets tough, Bauser comes into its own

Technology and solutions expertise are gearing skills: As a developer, manufacturer and partner, Bauser can supply plastic gear technology for even your most demanding of applications. The more challenging the task profiles, the more our customers turn to our plastic gears and spline components as well as to technical components such as worm drive components and plastic casings, all made by Bauser, products that often make a crucial difference in a vast array of diverse sectors.

Also make use of innovative materials and superior technologies. When plastic gears are what you need, place your confidence in Bauser!

Our references

For our customers right around the world, we develop and produce application-specific gears and gear components for a diverse range of transmission applications – optimized for noise and performance and also designed to contend with demanding operational environments.

For decades, this has been convincing to international top players from these sectors:

Automotive – mechanical engineering – transmission technology – home automation

A perfectly interconnecting sequence of processes, from advice to logistics

Premium partner Bauser

Seamless service begins at the start of a project. From Day One, our customers are supported by a central point of contact who is responsible for every single step. This is because Bauser is at one and the same time a developer, a manufacturer, a partner and, first and foremost, is a problem-solver. We open up our own frontiers with our network partners. This enables us to take your wishes on board, to understand them and to find solutions. Which in turn means that we can deliver quality in a seamless sequence extending right across the process chain.

Simulation & Prototyping

Simulating a component and the mold as a single unit ensures that costly defects can be avoided right from the start. Analysis of pressure losses and friction, weld lines and hotspots reveals valuable information for error prevention. We work with tools such as KISSsoft, Sigmasoft, Moldflow, and 3D-Print.

Logistics

Bauser delivers professionally and reliably wherever our international customers need plastic components or sub-assemblies: And that means on a worldwide basis. Whether in bulk or in customer-specific packaging units: We will find the right packaging and storage solution for your products, right up to consignment storage on the customer’s premises.

Welcome to the team

The core message of our company is ’gearing together’. Naturally, that also applies to our employees, not only to our customers and partners. While we encourage and challenge every employee, we always act as a team. Find out here what makes us so special, and learn which new team members we are looking to recruit, as professionals or for in-house training:

News & Diary Dates

Heuberg in film

We have made a financial commitment, helping to make the creation of the new Heuberg film possible: Get to know our location in a unique way – with great impressions and the authentic voices of the people who define this region.

Recycling for relaxation in the open-air

Take a moment to relax outside: Since a few days ago, that is now also possible here with us. We have Mr. Widmann to thank for this. He built these seating areas out of old wooden packaging, arranged them in front of our main building and, straightaway, all our employees can now use them during breaks and rest periods. We think this is a great initiative. Our grateful thanks to him for making this happen!

A successful summer party for everyone

At the Wehingen ski lodge, Bauser employees met for the big Summer Party to kick off the summer, prepared to perfection by the Bauser party committee: Our entire workforce had a great time together, enjoying a delicious BBQ from the Löwenstube Schörzingen, cool drinks, a cocktail bar, music courtesy of a DJ, a photo box, a prize draw, and live entertainment.